Volvo Penta D2-55 (B) Heat Exchange + Exhaust Elbow

The problem started some time ago when one of the raw water cooling hoses burst without notice and naturally just when we were entering the Port Douglas marina. With a generous amount of improvisation which included copious amounts of duck tape, we managed to limp into safety.

From there we did the thing that comes naturally which is trying to fix this as quickly and as cost-effectively as possible. We replaced the hose and all seemed fine.

There is no need mentioning that this was not the last of it.

There is an expression in Dutch that freely translates to “even a donkey doesn’t hit its head on the same rock twice”. We had another hose burst at an equally inconvenient time (as if there are convenient times to break down) and decided to replace all our hoses and be done with it.

To our surprise, two weeks later we blew a hose. By now, I started to feel very much worse than the proverbial donkey. Particularly, as we were on our way south for a 3-month trip. We replaced the new hose with another spare hose but the level of confidence in our engine was falling to new lows. Eventually, we run out of spare hose and decided to get to Townsville under sail and hope our last hose would get us in the marina.

During our last few hours of motoring, we noticed that there was some white smoke coming from the exhaust which we put down to perhaps some water in the primary fuel filter. We planed to service the engine whilst in Townsville which we did.

Like any other DIY – amateur – layman, you connect to your sailing forum and ask for advice.

We articulated our issues, described the symptoms and waited for the communal diagnosis and solution which almost came instantly and at various levels of quality.

The advice ranged from “wrong hose” or “blown head gasket” to more sensible suggestion pointing towards a blocked exhaust elbow.

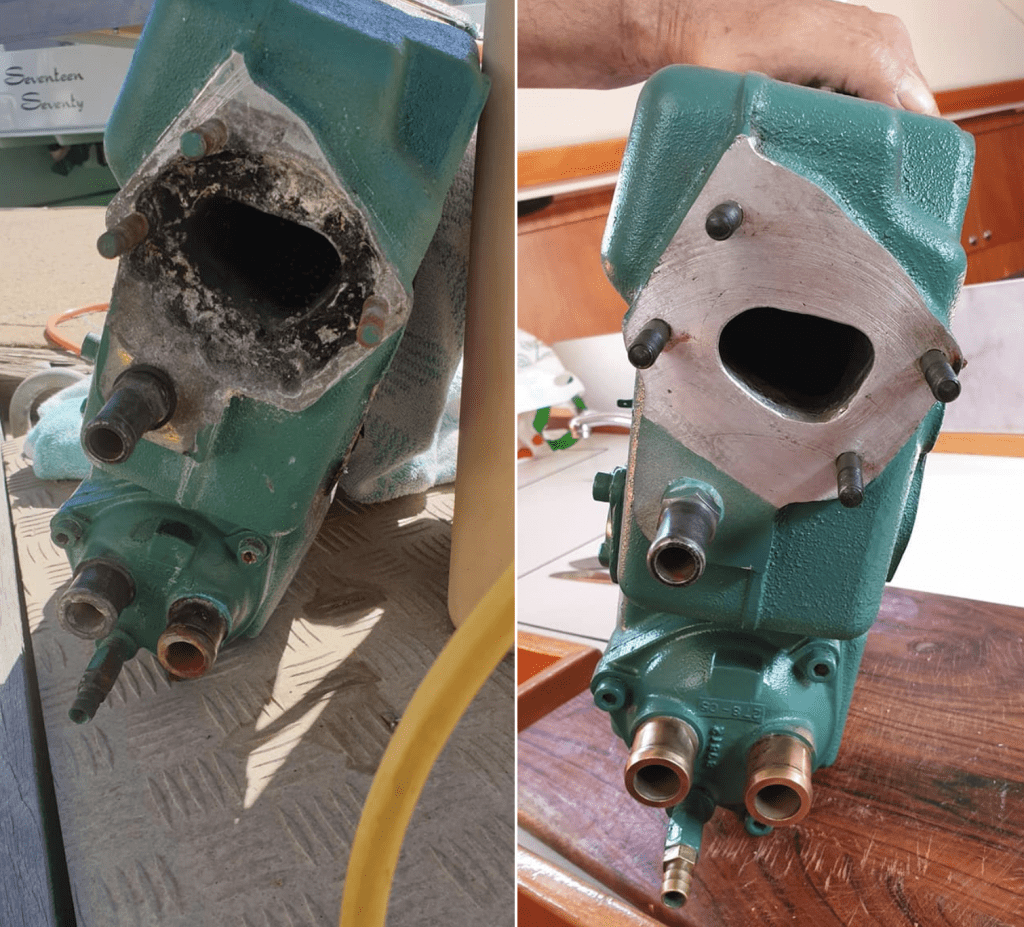

We then took the exhaust elbow off and on inspection, it was clear that this was, if not the issue, at least part of the issue. We ordered a new aftermarket elbow and on arrival proceeded to clean and prepare the heat exchange where the exhaust attaches. When lifting off the old gasket, the heat exchange revealed a hole that was clearly not standard issue. It looked like what can only be described as aluminium tooth decay. A small fist of aluminium was eaten away over the years and it was clear that this needed fixing.

After pricing a new heat exchange we desperately researched the possibility of repairing the old one. We didn’t have much hope as the decay was substantial but eventually found Cleaveland Bay Engineering & Marine.

To our surprise and great relief, Des (the owner) was feeling positive about getting the repairs done.

After a few days, our old heat exchange was ready to be picked up.

All expectations we had were exceeded. The guts of the exchange was disassembled, cleaned and reassembles. The giant decaying hole was filled in and looked like new. The 4 studs that hold the exhaust elbow were replaced. The whole unit was re-painted.

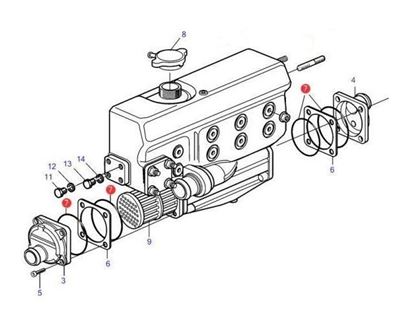

Putting the heat exchange back was relatively easy using a new gasket purchased from Rosshaven Marine. Attaching the exhaust elbow was also a breeze. The only issue we had was that the D2-55(B) has 25.4mm flanges where the hoses meet the pump and heat exchange but the after marker exhaust elbow had a 32mm flange so our hose didn’t fit. Again Rosshaven Marine supplied a couple of plumbing bits to reduce the 32mm to 25.4mm.

Now see is purring like a kitten again.

In a nutshell...

Symptoms

- Bulging raw water hoses

- Bursting raw water hoses

- Raw water hoses blown of their flanges.

- Reduced power.

- Low water flow from the exhaust

- White smoke from the exhaust

Solution

- Inspect exhaust elbow

- Acid clean or replace if necessary

- Inspect heat exchange

- Clean / repair as needed

- Replace hoses and clamps

- Replace coolant